The role and importance of bearing preload

When it comes to bearing preload, I believe many people do not know much about it. Applications such as machine tool spindles, electric motors, and automotive differentials require precise rotational motion with high stiffness and positional accuracy. For this reason, a constant load must be applied to the bearing during assembly to eliminate excess play. Today, we will explain in detail the role and importance of bearing preload.

1. What is bearing preload

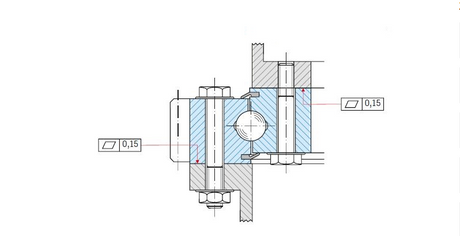

Preload is to apply a force to the bearing in advance before installation or use, so that the bearing has a certain deformation. Generally, the rolling bearing has a certain clearance in the working state. The purpose of this is to eliminate the deformation of the bearing after installation. Due to the influence of workpiece or accuracy, when arranging the bearing, the bearing obtains a certain internal load through a certain adjustment method, and is used in a negative clearance state. According to the needs of the working conditions, select the appropriate preload force. Generally, the preload force of the bearing is certain. Therefore, the preload of the bearing is very important for the operation of the bearing.

Second, the role of bearing preload

The main functions of bearing preload include: improving rotation accuracy, reducing noise, compensating for wear during operation, improving rigidity, and extending working life.

1. The effect of improving the rotation accuracy

After the bearing is preloaded, the internal clearance is eliminated, and each rolling element bears a certain preload, supporting the ferrule from all directions, which can improve the rotation accuracy, enable the shaft to be positioned correctly in the axial and radial directions, and improve the shaft. Rotational accuracy, such as machine tool spindle bearings and measuring instruments.

2. Improve the working life of the bearing

After preloading, the number of loaded rolling elements increases, the load on each rolling element decreases, and the load can be distributed evenly on each rolling element, so the life of the bearing can be improved.

3. Improve stiffness

The contact between the rolling element and the raceway is elastic contact, and the rolling element can be regarded as a spring. Bearings with clearance are only supported by a few springs in the direction of force. The preloaded bearing is supported by springs in all directions, and has a certain amount of preload, and the number of rollings under the load is more than that of the bearing, so the rigidity can be improved. In ball bearings, the relationship between the contact deformation of the ball and the raceway and the load is nonlinear, and the contact stiffness increases with the increase of the preload.

4. Improve bearing damping and reduce noise

The preload can establish a stable oil film between the rolling element and the raceway, improve the damping between the rolling element and the raceway, improve the dynamic characteristics of the support structure and reduce the noise.

5. Inhibit vibration lines and friction and wear

The outer spherical bearing is actually a variant of the deep groove ball bearing. The outer spherical bearing is mainly used to bear the combined radial and axial load mainly based on the radial load, and it is generally not suitable to bear the axial load alone. It is used for vibration-free machining of low-roughness machining machines, or in mechanisms that need to control friction and wear when starting and stopping frequently.

6. Improve the dynamic performance of angular contact ball bearings

In high-speed rotating angular contact ball bearings, proper preload can prevent the gyroscopic rotation of the steel ball, prevent or reduce the revolving slip of the steel ball, and control the spin sliding of the steel ball.

7. Compensate for wear during operation

The bearing will increase the clearance due to wear during operation, which can be compensated by preloading.

8. Control the slip phenomenon of rolling body revolution and rotation

Spherical bearing with seat This type of bearing also has a certain self-alignment in design, easy to install, and has a double-structured sealing device, which can work in harsh environments. The bearing seat is generally cast. Bearings with housings are high-precision components made up of grease-sealed deep groove ball bearings and housings of various shapes.

The bearing assembly can be directly installed on the main body of the mechanical device through several bolts, has the self-aligning function, can supplement the grease, etc. It is a product that is very easy to install and use. Such as radial thrust ball bearings used in high-frequency motors and cylindrical roller bearings on jet engines.

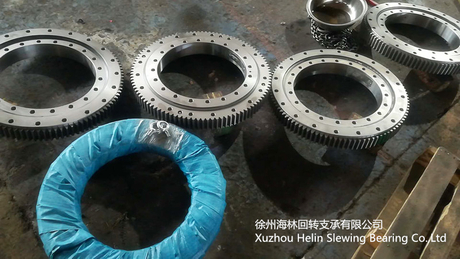

The above is an introduction to the role and importance of bearing preload. It should be noted that excessive preload will increase the friction, wear and temperature rise of the bearing, reduce the noise and grease life of the rolling bearing, and cause excessive damage to the bearing. Therefore, it is very important to choose a suitable preload. our company Xuzhou Helin Slewing Bearing is a comprehensive entity enterprise integrating design, research and development, production, sales and service of slewing bearing/slewing bearing. It mainly produces slewing ring/turntable bearing and non-standard special-shaped bearing/pinion/flange with a diameter of 100-5000mm. The precision covers four grades of P0, P6, P5, and P4. The product types include single-row four-point contact ball structure, Cross cylindrical roller structure, three-row cylindrical roller structure, double-row ball structure, ball-column combined structure, thin-walled flange structure, large thrust ball structure, etc. In addition, according to customer needs, we can implement personalized optimization design and customized flexible production of suitable products for different customers. Welcome to call for detailed consultation.

English

English