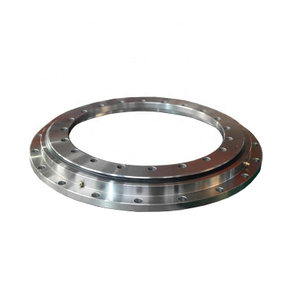

The light slewing bearing has the same structure form as the ordinary slewing bearing, with light weight and flexible rotation. Widely used in food machinery, filling machinery, environmental protection machinery and other fields.

1. Slewing bearing support structure

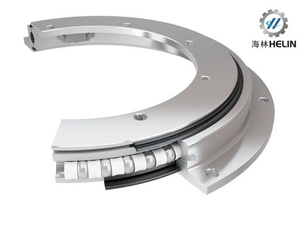

The slewing bearing rolling elements are usually separated by individual nylon spacers. This structure can maintain the smoothness of the movement, and the price is low, so it is widely used. Special applications need to use special ball or roller isolation blocks, such as copper, aluminum and other high-temperature isolation. Generally, bearings installed on horizontal shafts or continuously rotating generators and slewing bearings used in occasions with high requirements for positioning and reliability can use strip combined cages to keep the rolling elements in the correct position. Circumferential position, higher reliability.

2. Working principle of slewing ring

The working principle of the slewing bearing is very simple: the way to move the object is from sliding to rolling to reduce frictional resistance.

Specifically, the slewing bearing mainly relies on lubrication and friction to achieve the results of operation. Internally, it relies on the friction between the balls and the steel ring to achieve the purpose of operation. On the outside, it also relies on the friction of the slewing bearing and other parts to start operation and rub against each other, thereby driving the operation of the object. Because it is mostly used to carry heavy and large objects, its centripetal force is very demanding, which is also determined by its working principle, so in terms of materials, it also needs to be able to ensure the quality of steel.

Of course, friction alone is not enough. Although it depends on friction to operate, lubrication is also essential. Just like a bicycle chain, it takes a long time and excessive friction will affect the use of parts. Therefore, after using this kind of bearing for a period of time, it is necessary to carry out maintenance in time and brush some lubricating oil to ensure that it can work in a more suitable environment.

Mob/ Whatsapp / Wechat : + 86- 180 8679 0390

Tel : + 86 -516- 8788 0390

Email : info@helin-bearing.com

tinaxzhelin@gmail.com

Please do not hesitate to reach our to us if you have any further questions.

Floowing slewing bearing size information :

Note:

1. n1 is the nos of lubricating holes.Oil cup M8×1JB/T7940.1~JB/T7940.2.The Oil nipple's location can be change according to the user's application.

2. "Km" is addendum reduction.

Model

DL | Wght | Dimensions | Mounting dimension | Structural dimension | Gear data | Gear | Clearance |

| circumferential |

| kg | force |

| D | de | H | D1 | D2 | na | Φ/M | ni | Φ/M | t | n1 | D3 | d1 | C | Hu | d | m | z | b | k.m | Allowed | Max | Axial | Radial |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | KN | [KN] |

| H-231.20.0414 | 29 | 504 | 304 | 56 | 455 | 332 | 10 | M12 | 24 | 18 | 20 | 4 | 412.5 | 415.5 | 375 | 10.5 | 495 | 5 | 99 | 45.5 | -0.5 | 11.75 | 23.5 | ≤0.5 | ≤0.5 |

| H-231.20.0544 | 39.2 | 640.8 | 434 | 56 | 585 | 462 | 14 | M12 | 28 | 18 | 20 | 4 | 542.5 | 545.5 | 505 | 10.5 | 630 | 6 | 105 | 45.5 | -0.5 | 14.2 | 28.4 | ≤0.5 | ≤0.5 |

| H-231.20.0644 | 47.2 | 742.8 | 534 | 56 | 685 | 562 | 16 | M12 | 32 | 18 | 20 | 4 | 642.5 | 645.5 | 605 | 10.5 | 732 | 6 | 122 | 45.5 | -0.6 | 14.2 | 28.4 | ≤0.5 | ≤0.5 |

| H-231.20.0744 | 53.1 | 838.8 | 634 | 56 | 785 | 662 | 18 | M12 | 32 | 18 | 20 | 4 | 742.5 | 745.5 | 705 | 10.5 | 828 | 6 | 138 | 45.5 | -0.6 | 14.2 | 28.4 | ≤0.5 | ≤0.5 |

| H-231.20.0844 | 64.7 | 950.4 | 734 | 56 | 885 | 762 | 18 | M12 | 36 | 18 | 20 | 4 | 842.5 | 845.5 | 805 | 10.5 | 936 | 8 | 117 | 45.5 | -0.8 | 18.93 | 37.86 | ≤0.5 | ≤0.5 |

| H-231.20.0944 | 69.1 | 1046 | 834 | 56 | 985 | 862 | 20 | M12 | 40 | 18 | 20 | 4 | 942.5 | 945.5 | 905 | 10.5 | 1032 | 8 | 129 | 45.5 | -0.8 | 18.93 | 37.86 | ≤0.5 | ≤0.5 |

| H-231.20.1094 | 82.5 | 1198 | 984 | 56 | 1135 | 1012 | 22 | M12 | 40 | 18 | 20 | 4 | 1093 | 1095.5 | 1055 | 10.5 | 1184 | 8 | 148 | 45.5 | -0.8 | 18.93 | 37.86 | ≤0.5 | ≤0.5 |

English

English