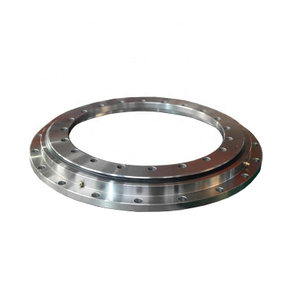

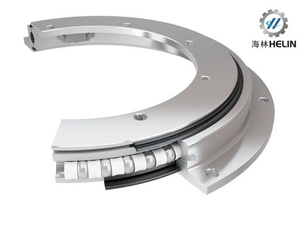

Slewing Bearing with Flange -- Internal Gear

Characteristic of structure, performance and application

The Thin Section Slewing Bearing has the same structure with the ordinary slewing bearing,but the weight is light,and rotate flexibly,which widely used in the food machinaery,canning machinery and environmental machinery etc.

OUR ADVANTAGE:

1. Fast: Be good at adapting, simple organization, high working efficiency, be creative and accept all kinds of customization.

2. Flexible: streamlined personnel, short communication path, and problems can be solved quickly , perfect after -sales services .

3. Efficient: employees have higher comprehensive ability, high work efficiency, high output, good quanlity and short product delivery time.

WHY CHOOSE HELIN :

1,Helin slewing bearing is located in Xuzhou, a very famous Construction Machinery Base, and has its own stable, technically sound design, development, and manufacturing team.

2. The physical factory has a strong R&D team, and production equipment is advanced, production equipment is continuously increased and updated, and there are molding batch production lines with clear division of labor and high production efficiency. (Standard models with raw material in stock , delivery time within 7 days . )

3. The slewing bearing is exported to more than 30 countries, which obtain high praise and recognition from customers all over the world .And our engineer can come to your country to do measurements .

Mob/ Whatsapp / Wechat : + 86- 180 8679 0390

Tel : + 86 -516- 8788 0390

Email : info@helin-bearing.com

tinaxzhelin@gmail.com

Please do not hesitate to reach our to us if you have any further questions.

Note:

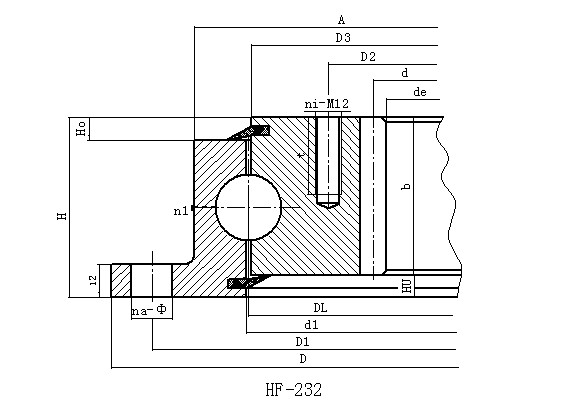

1. n1 is the nos of lubricating holes.Oil cup M8×1JB/T7940.1~JB/T7940.2.The Oil nipple's location can be change according to the user's application.

2. "Km" is addendum reduction.

Model

DL | Wght | Dimensions | Mounting dimension | Structural dimension | Gear data | Gear | Clearance |

| circumferential |

| [kg] | force |

| D | de | H | D1 | D2 | na | Φ/M | ni | Φ/M | t | n1 | D3 | d1 | A | Hu | d | m | z | b | k.m | Allowed | Max | Axial | Radial |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | KN | KN |

| H-232.20.0414 | 26.9 | 518 | 326.5 | 56 | 490 | 375 | 16 | 18 | 12 | M12 | 20 | 4 | 412.5 | 415.5 | 453 | 10.5 | 335 | 5 | 67 | 45.5 | -0.75 | 13.54 | 27.08 | ≤0.5 | ≤0.5 |

| H-232.20.0544 | 36.7 | 648 | 445.5 | 56 | 620 | 505 | 20 | 18 | 16 | M12 | 20 | 4 | 542.5 | 545.5 | 583 | 10.5 | 456 | 6 | 76 | 45.5 | -0.6 | 16 | 32 | ≤0.5 | ≤0.5 |

| H-232.20.0644 | 43.4 | 748 | 547.5 | 56 | 720 | 605 | 24 | 18 | 18 | M12 | 20 | 4 | 642.5 | 645.5 | 683 | 10.5 | 558 | 6 | 93 | 45.5 | -0.6 | 15.62 | 31.24 | ≤0.5 | ≤0.5 |

| H-232.20.0744 | 50.8 | 848 | 649.2 | 56 | 820 | 705 | 24 | 18 | 20 | M12 | 20 | 4 | 742.5 | 745.5 | 783 | 10.5 | 660 | 6 | 110 | 45.5 | -0.6 | 15.32 | 30.64 | ≤0.5 | ≤0.5 |

| H-232.20.0844 | 61.3 | 948 | 737.6 | 56 | 920 | 805 | 28 | 18 | 20 | M12 | 20 | 4 | 842.5 | 845.5 | 883 | 10.5 | 752 | 8 | 94 | 45.5 | -0.8 | 20.8 | 41.6 | ≤0.5 | ≤0.5 |

| H-232.20.0944 | 65.4 | 1048 | 841.6 | 56 | 1020 | 905 | 32 | 18 | 22 | M12 | 20 | 4 | 942.5 | 945.5 | 983 | 10.5 | 856 | 8 | 107 | 45.5 | -0.8 | 20.49 | 40.98 | ≤0.5 | ≤0.5 |

| H-232.20.1094 | 80.3 | 1198 | 985.6 | 56 | 1170 | 1055 | 32 | 18 | 24 | M12 | 20 | 4 | 1092.5 | 1096 | 1133 | 10.5 | 1000 | 8 | 125 | 45.5 | -0.8 | 20.16 | 40.32 | ≤0.5 | ≤0.5 |

English

English