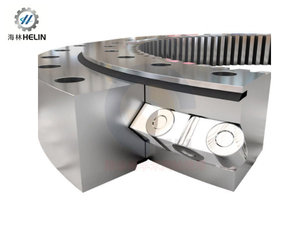

The heat treatment of slewing bearing track and gear, also called quenching treatment, is that the raceway of slewing bearing is subject to surface induction quenching treatment, and the quenching hardness ensures that the qualified quenching layer depth can be achieved with different track diameter, steel ball size and quenching layer depth at HRC55 ~ 62.

Due to the need of transmitting force, one ring of slewing ring is usually made with teeth. The heat treatment state of gear is generally quenched and tempered, and the hardness is 207 ~ 262hb. The tooth surface with special requirements can also be quenched according to the user's requirements. The quenching hardness is HRC55 ± 5 and can ensure sufficient depth. According to different applications, gear quenching can be divided into full tooth quenching and single tooth induction quenching. Single tooth induction quenching can be divided into tooth surface root quenching and tooth surface quenching.

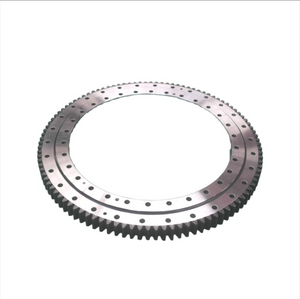

External gear single row ball four-point

The single-row four-point contact ball slewing ring is composed of two seat rings and has a compact structure. The steel ball contacts the arc raceway at four points. The size of the single-row ball slewing ring is large, mainly 0.4 to 10 meters, and some up to 40 meters, which can withstand several aspects of pressure. In addition, the single-row ball slewing bearing has a low operating speed and can achieve continuous rotation. The single-row ball slewing bearing has a relatively strong bearing capacity, can bear axial force, radial force and tilting moment, and can realize continuous rotation, especially reciprocating rotation within a certain angle, which is equivalent to the so-called "swing bearing".

Mainly used for truck cranes, tower cranes, excavators, pile drivers, graders, road rollers, dynamic compactors, rock drilling machinery, engineering vehicles, radar scanning equipment, etc. to bear the overturning moment, vertical axial force, and horizontal inclination force.

Please find the following slewing bearing size information :

Note:

1. n1 is the nos of lubricating holes.Oil cup M10×1JB/T7940.1~JB/T7940.2.The Oil nipple's location can be change according to the user's application.

2. n-φcan change to tapped hole,the diameter of tapped hole is M,depth is 2M.

3. The tangential tooth force in the form is the max tooth force,the nominal tangential tooth force is 1/2 of the max one.

4. "K" is addendum reduction coefficient.

| No. | External gear | Dimensions | Mounting Dimensions | Structural Dimension | Gear circumferential force | Gear circumferential force | Weight |

| DL |

| mm | D | d | H | D1 | D2 | n | mm | n1 | D3 | d1 | H1 | h | b | x | m | De | z | Quenching | kg |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | T 104N |

|

| 1 | HJW.20.625 | 725 | 525 | 80 | 685 | 565 | 18 | 18 | 3 | 627 | 623 | 68 | 12 | 60 | 1.4 | 5 | 751.9 | 146 | 5.2 | 100 |

| HJW.20.625A | 1.15 | 6 | 755.5 | 122 | 6.2 |

| 2 | HJW.20.720 | 820 | 620 | 80 | 780 | 660 | 18 | 18 | 3 | 722 | 718 | 68 | 12 | 60 | 1.4 | 6 | 860.3 | 139 | 6.2 | 120 |

| HJW.20.720A | 1 | 8 | 861.1 | 104 | 8.3 |

| 3 | HJW.30.820 | 940 | 705 | 95 | 893 | 749 | 24 | 20 | 4 | 822 | 818 | 83 | 12 | 70 | 1.4 | 6 | 980.6 | 159 | 7.2 | 210 |

| HJW.30.820A | 1 | 10 | 986.2 | 95 | 12.2 |

| 4 | HJW.30.880 | 1000 | 760 | 95 | 956 | 800 | 24 | 20 | 4 | 882 | 878 | 83 | 12 | 70 | 1.15 | 8 | 1047.5 | 127 | 9.7 | 230 |

| HJW.30.880A | 1 | 10 | 1046.3 | 101 | 12.2 |

| 5 | HJW.30.1020 | 1170 | 875 | 95 | 1120 | 930 | 24 | 22 | 4 | 1022 | 1018 | 80 | 15 | 70 | 1.4 | 8 | 1219.3 | 148 | 9.7 | 300 |

| HJW.30.1020A | 1.15 | 10 | 1219.2 | 118 | 12.2 |

| 6 | HJW.36.1220 | 1365 | 1075 | 120 | 1310 | 1130 | 36 | 24 | 6 | 1222 | 1218 | 105 | 15 | 90 | 1.4 | 10 | 1424.9 | 138 | 15.7 | 450 |

| HJW.36.1220A | 1 | 12 | 1435.9 | 116 | 18.8 |

| 7 | HJW.36.1250 | 1400 | 1090 | 120 | 1350 | 1150 | 36 | 26 | 6 | 1252 | 1248 | 105 | 15 | 90 | -0.35 | 10 | 1443 | 143 | 15.7 | 520 |

| HJW.36.1250A | 1 | 12 | 1449.6 | 117 | 18.8 |

| 8 | HJW.36.1435 | 1595 | 1278 | 120 | 1535 | 1335 | 36 | 26 | 6 | 1437 | 1433 | 105 | 15 | 90 | 1.15 | 12 | 1655.5 | 134 | 18.8 | 610 |

| HJW.36.1435A | 1 | 14 | 1661.2 | 115 | 21.9 |

| 9 | HJW.45.1540 | 1720 | 1360 | 140 | 1660 | 1420 | 42 | 26 | 6 | 1543 | 4537 | 122 | 18 | 110 | 1.4 | 12 | 1780.8 | 144 | 23 | 732 |

| HJW.45.1540A | 1.15 | 14 | 1791.1 | 124 | 26.8 |

| 10 | HJW.45.1700 | 1875 | 1525 | 140 | 1815 | 1585 | 42 | 29 | 6 | 1703 | 1697 | 122 | 18 | 110 | 1.15 | 14 | 1945.4 | 135 | 26.8 | 844 |

| HJW.45.1700A | 1.15 | 16 | 1950.8 | 118 | 30.5 |

| 11 | HJW.45.1880 | 2100 | 1665 | 160 | 2030 | 1740 | 48 | 32 | 6 | 1883 | 1876 | 140 | 20 | 115 | 1.4 | 14 | 2189.8 | 152 | 27.8 | 1400 |

| HJW.45.1880A | 1.15 | 18 | 2194.6 | 118 | 35.8 |

| 12 | HJW.45.2115 | 2325 | 1900 | 160 | 2245 | 1980 | 48 | 32 | 6 | 2118 | 2112 | 140 | 20 | 115 | 1.4 | 16 | 2406.5 | 146 | 31.9 | 1600 |

| HJW.45.2115A | 1.15 | 20 | 2418.4 | 117 | 40 |

| 13 | HJW.45.2370 | 2600 | 2146 | 180 | 2520 | 2220 | 48 | 32 | 6 | 2373 | 2367 | 158 | 22 | 130 | 1.4 | 18 | 2707.3 | 146 | 40.7 | 2100 |

| HJW.45.2370A | 1.15 | 22 | 2704.4 | 119 | 49.7 |

| 14 | HJW.45.2600 | 2835 | 2365 | 180 | 2750 | 2450 | 54 | 36 | 6 | 2603 | 2597 | 158 | 22 | 130 | 1.4 | 18 | 2941.7 | 159 | 37.6 | 2400 |

| HJW.45.2600A | 1.15 | 22 | 2946.9 | 130 | 45.9 |

| 15 | HJW.50.2820 | 3085 | 2555 | 200 | 3000 | 2640 | 54 | 36 | 6 | 2823 | 2817 | 178 | 22 | 150 | 1.4 | 20 | 3188.4 | 155 | 52.2 | 3400 |

| HJW.50.2820A | 1.15 | 25 | 3198.4 | 124 | 65.3 |

| 16 | HJW.50.3120 | 3400 | 2840 | 200 | 3310 | 2930 | 54 | 36 | 6 | 3123 | 3117 | 178 | 22 | 150 | 1.4 | 22 | 3507.2 | 155 | 57.4 | 4000 |

| HJW.50.3120A | 1.4 | 25 | 3509.6 | 136 | 65.3 |

| 17 | HJW.50.3580 | 3920 | 3240 | 240 | 3820 | 3340 | 60 | 40 | 6 | 3583 | 3577 | 218 | 22 | 190 | 1.4 | 22 | 4036.1 | 179 | 72.7 | 6700 |

| HJW.50.3580A | 1.4 | 25 | 4035.6 | 157 | 82.6 |

| 18 | HJW.50.4030 | 4370 | 3690 | 240 | 4270 | 3790 | 66 | 40 | 6 | 4033 | 4027 | 218 | 22 | 190 | 1.4 | 22 | 4520.6 | 201 | 53.6 | 7700 |

| HJW.50.4030A | 1.4 | 28 | 4522.4 | 157 | 68.2 |

| 19 | HJW.50.4540 | 4860 | 4210 | 240 | 4760 | 4310 | 72 | 40 | 6 | 4543 | 4537 | 218 | 22 | 190 | 1.4 | 22 | 4983.1 | 222 | 72.1 | 8760 |

| HJW.50.4540A | 1.4 | 30 | 4992.9 | 162 | 99.1 |

English

English