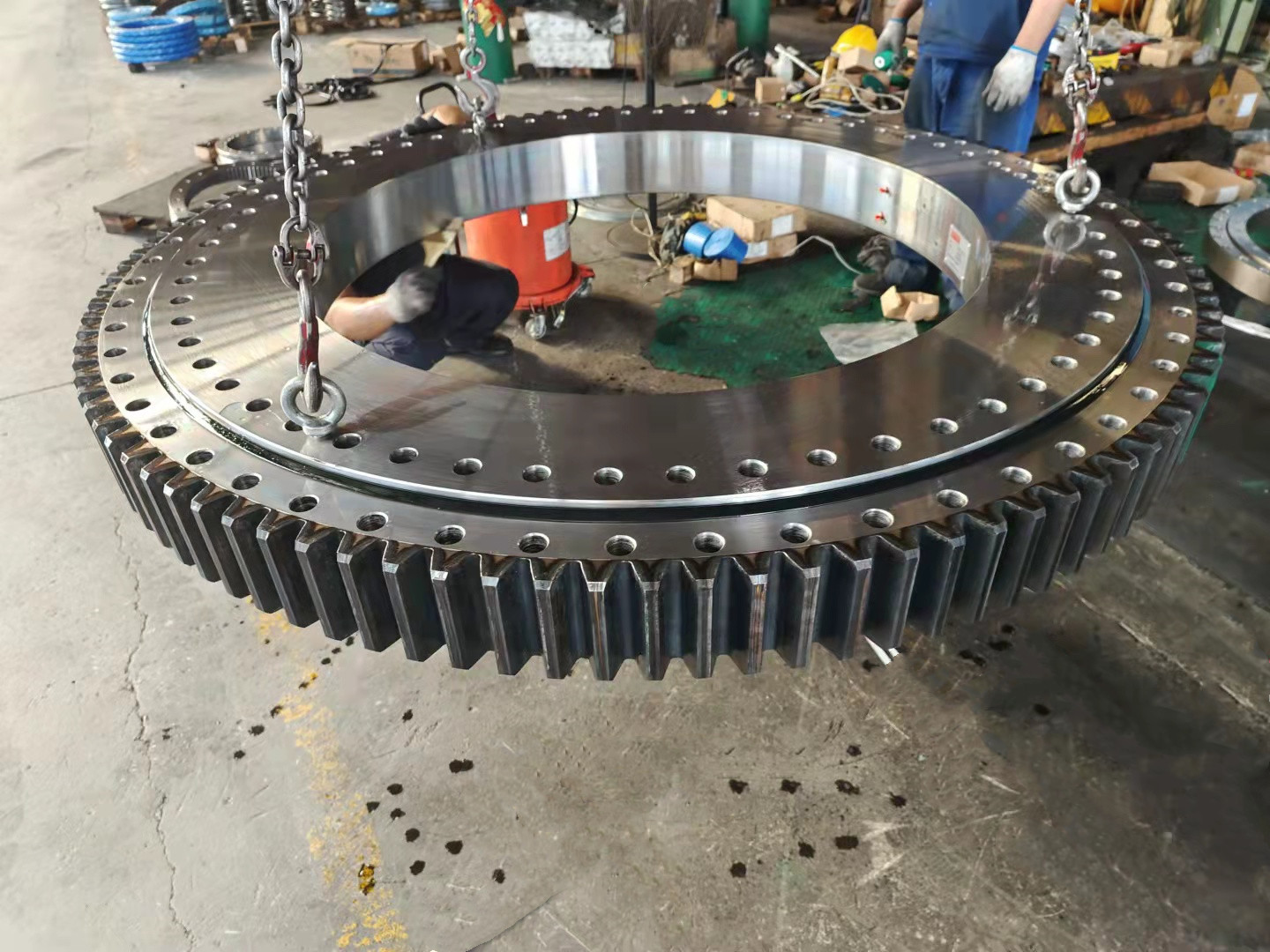

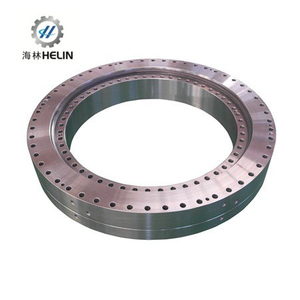

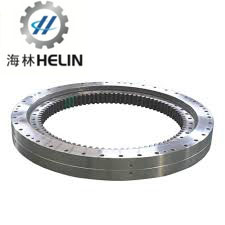

How to maintain your slewing ring

Your crane will endure a lot during each project and will influence the wear on your crane. Most slewing bearing failures are due to lubrication problems, contamination, overloading, and improper installation and mounting fits. These failures occur much earlier than normal fatigue failures. To help you maintaining good function of your crane's slewing ring we have put together a few tips.

Slewing ring lubrication

The Slewing ring should be lubricated at regular intervals, with a heavy-duty, grease. Mobile cranes, Luffing cranes, tower cranes, crawler cranes and any other slow rotating cranes should be lubricated about every 100 hours of operation.

Over long periods of time, grease tends to dry out and condensation can form within a Slewing ring. Grease should therefore be introduced at least every six months, even when you don’t use the crane.

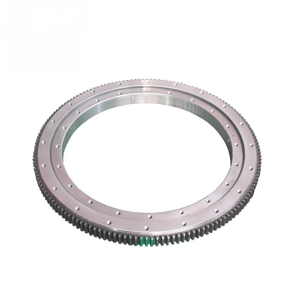

Lubrication of the teeth

The teeth of the slewing ring get much more wear then the bearings therefore, the lubrication requirements are not the same as for the slewing ring at itself. When using your crane, the teeth should be lubricated every eight hours this is because the meshing action of the teeth tends to squeeze out lubricant. To make this task easier a central lubrication system can be installed.

Maintaining slewing ring bolts

When in use, your crane tends to vibrate and shock, which can loosen the slewing ring bolts. A check of bolt torque must be done regularly and should be part of a routine maintenance procedure.

Detection of bearing wear makes repair a less costly alternative to replacement. If you practice proper maintenance and watch for common warning signs, a worn bearing is likely to be deemed repairable.

English

English