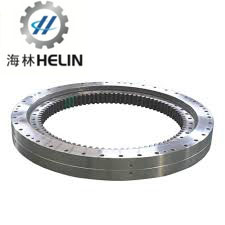

Xuzhou helin slewing bearing manufactures customized spur gears according to your 2D engineering drawings or 3D models, worn parts or samples. We will make them from 42CrMo, 40Cr or 45# Steel, or we will take your sample gears and test them to determine the material and hardness. Either way, you will receive customized spur gears manufactured according to your customized requirements.

Spur gear is designed to run on parallel shaft to transfer motion and power, which is the most commonly used choice for slewing bearing.

Spur gear is the most popular form and the most efficient gear device for transferring power and uniform rotary motion from one parallel shaft to another, and its cost is very high. Within the limit of center distance, spur gear provides positive constant speed drive, and its speed can be increased or decreased by increasing or decreasing the number of teeth in the driving gear. Spur gear can run in the "gear train" of two or more gears, but they must all have the same radial pitch and pressure angle.

English

English