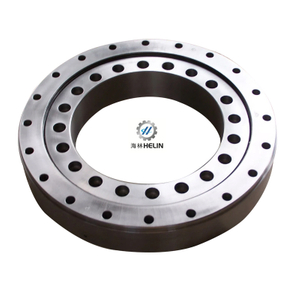

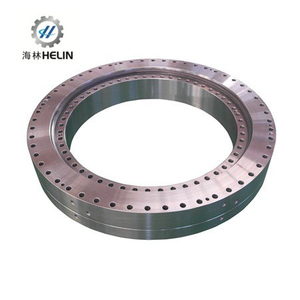

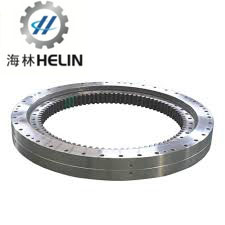

slewing bearing for marine crane

installation site

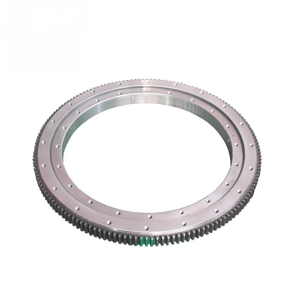

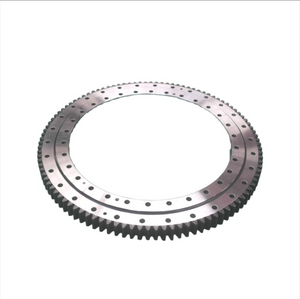

The ship crane is mainly composed of rotating tower, boom, fixed base post welded to the deck, lifting, tilting and swinging mechanism, hydraulic power and piping system, electrical control system,etc. Marine crane has turntable bearings mounted on the bottom of the crane tower body.The lower end of the inner ring is connected with the fixed base column that welded to the deck of the ship by bolts. The upper end of the outer ring is connected with the crane tower by bolts. When the ship crane is working, the swing pinion is driven by the swing mechanism and engaged with the ring inside the turntable bearing, so as to achieve the rotation of the outer ring, thus realizing the normal swing of the ship crane.

Force characteristics and common bearing structure

The functionality of the turntable bearings is to support the ship crane and transfer torque. It mainly withstands axial force and tilt torque. In order to make the main frame compact, the diameter and height of the bearing are much smaller than normal products, and do not set counterweight. Its tipping torque can reach 18 times axial force, the ratio of the two is basically between 14. 9 and 18. The most commonly used structures are the double-row ball bearings and the three rows cylindrical roller turntable bearings . The double-row ball bearings have the following characteristics: it can withstand a large collapse moment, more suitable for the working condition of the crane, has relatively strong ability to resist the unevenness of the bottom plate, can make up for the processing error of the connection parts, radial size is relatively small.

Force calculation

The speed of the bearing of the crane is generally below 1 r/m. At present, the limit loading capacity can be verified according to the tilting state of the ship, and each classification society has different methods to calculate the force of the bearing.

Materials

At present, usually we select 42 Cr Mo alloy tempered steel as the bearing material. Apart from normal bearing mechanical performance requirements, it should also : (1) in – 20! The average of the 3 specimens of the V-shaped shock absorption function should not be less than 42 J, and one of the specimens should be no less than 27 J; (2) The conditioning hardness of the ring reaches 260 to 290 H B. The material of the steel ball is commonly used bearing steel, which is not different from the general turntable bearing.

The sealing of the turntable bearing

The marine crane turntable bearings in the course of work is very vulnerable to seawater and other external objects. In order to prevent seawater from causing premature failure of bearings, the sealing of the bearing uses a double-lip rubber sealing structure, and use stainless steel wire to clamp on the inner ring , the structure can effectively prevent the erosion of seawater, and make it easy to replace. The sealing effect is reliable.

English

English